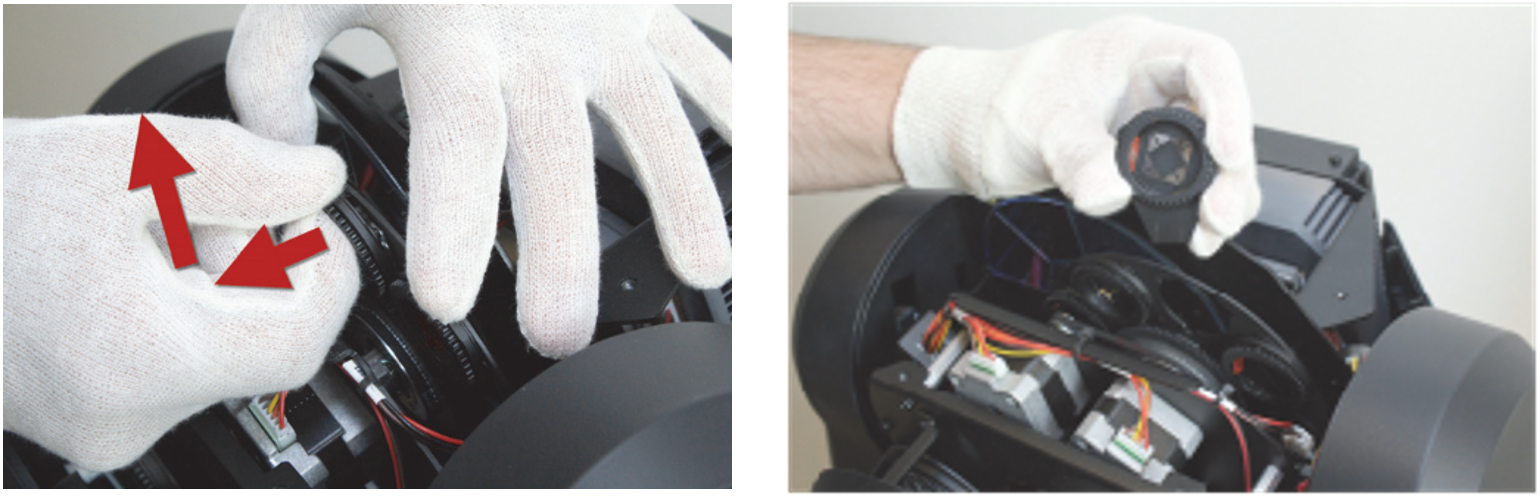

3. The rotating gobos sit in gobo holders that slot into clips in the rotating gobo wheel. Find the gobo you want to replace. See below. Pull its gobo holder away from the gobo wheel slightly, then lift the gobo holder out of its clip in the wheel.

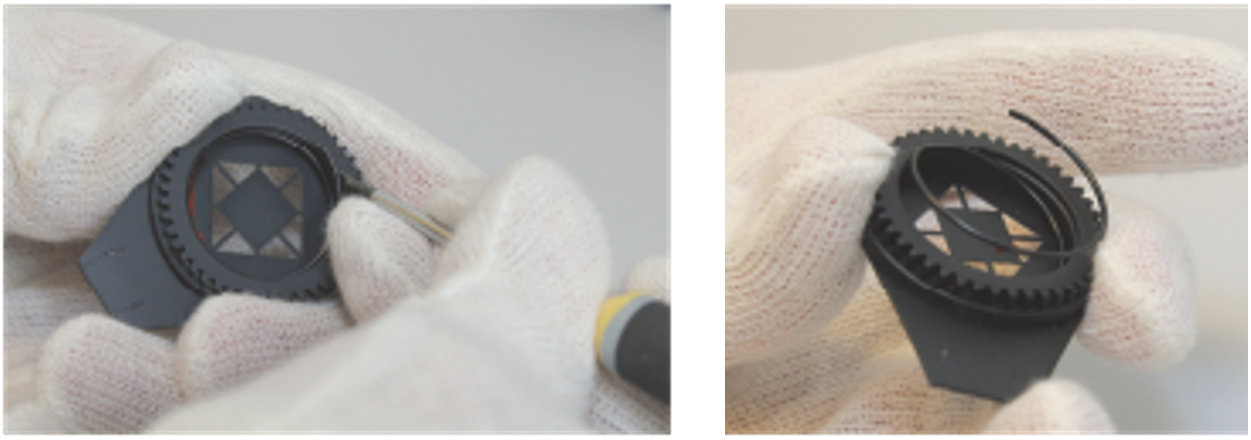

4. The gobo is held in place on the blade by a retaining spring. Use a flat- bladed screwdriver to lever the end of the spring out of its slot, then lift the spring out of the gobo holder.

5. A small amount of locking fluid is applied at the factory to prevent gobos from rotating in gobo holders. Remove the gobo from the holder, freeing it from the locking fluid.

6. Insert the new gobo and apply a small amount of red Loctite or similar locking fluid to the edge of the gobo and the gobo holder.

7. Reassemble following the steps above in reverse order. Pay particular attention to the following points during reassembly:

• Make sure that the gobo retaining spring is held firmly in its slot in the gobo holder.

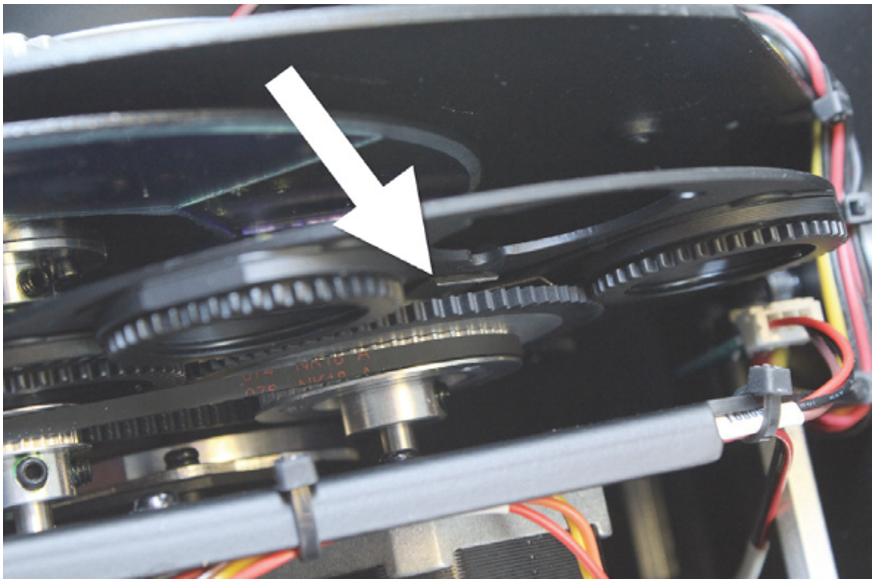

• Slide the tab on the gobo holder under the clip on the gobo wheel (see below) and make sure that the teeth on the gobo holder engage correctly in the cog in the center of the gobo wheel.

8. Reinstall the head cover and be ready for the head to move during a reset before reapplying power.